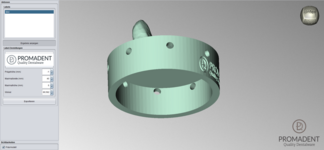

With MILLING to the milling model without plaster

- 30% faster than BISS milling models

- Direct start possible, without creating jobs

- Work system independent

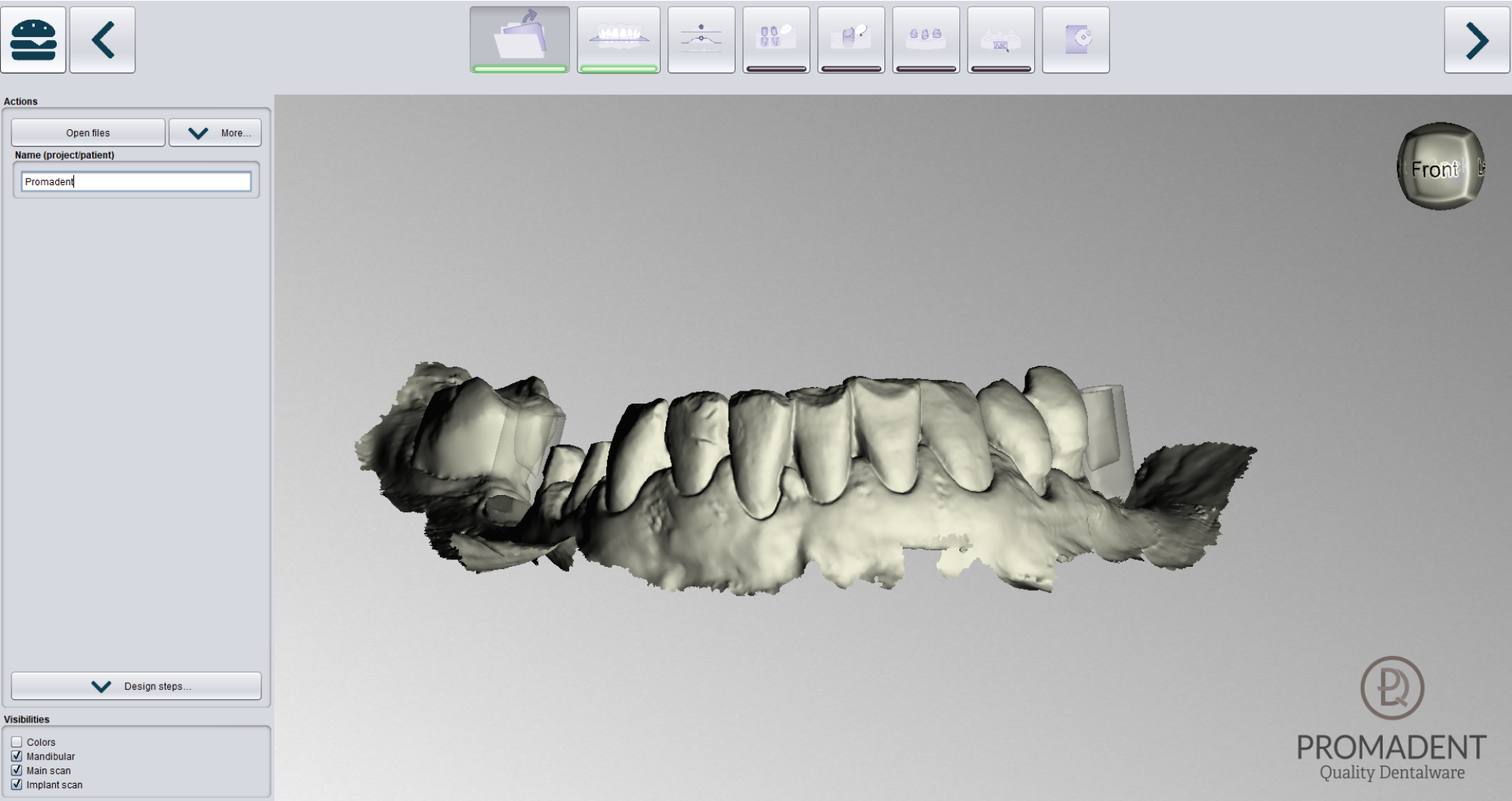

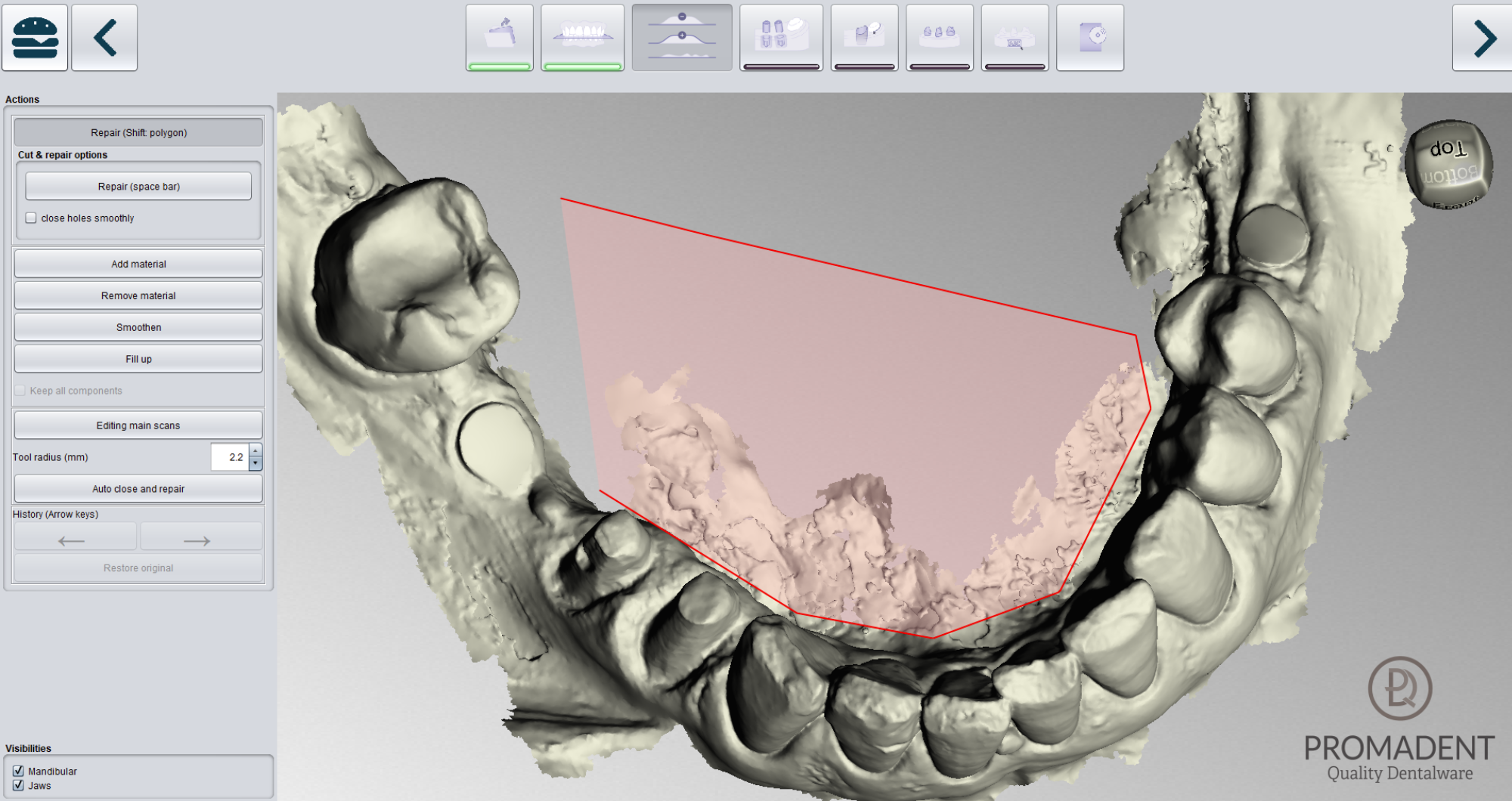

- Conversion of scan data into a printable model

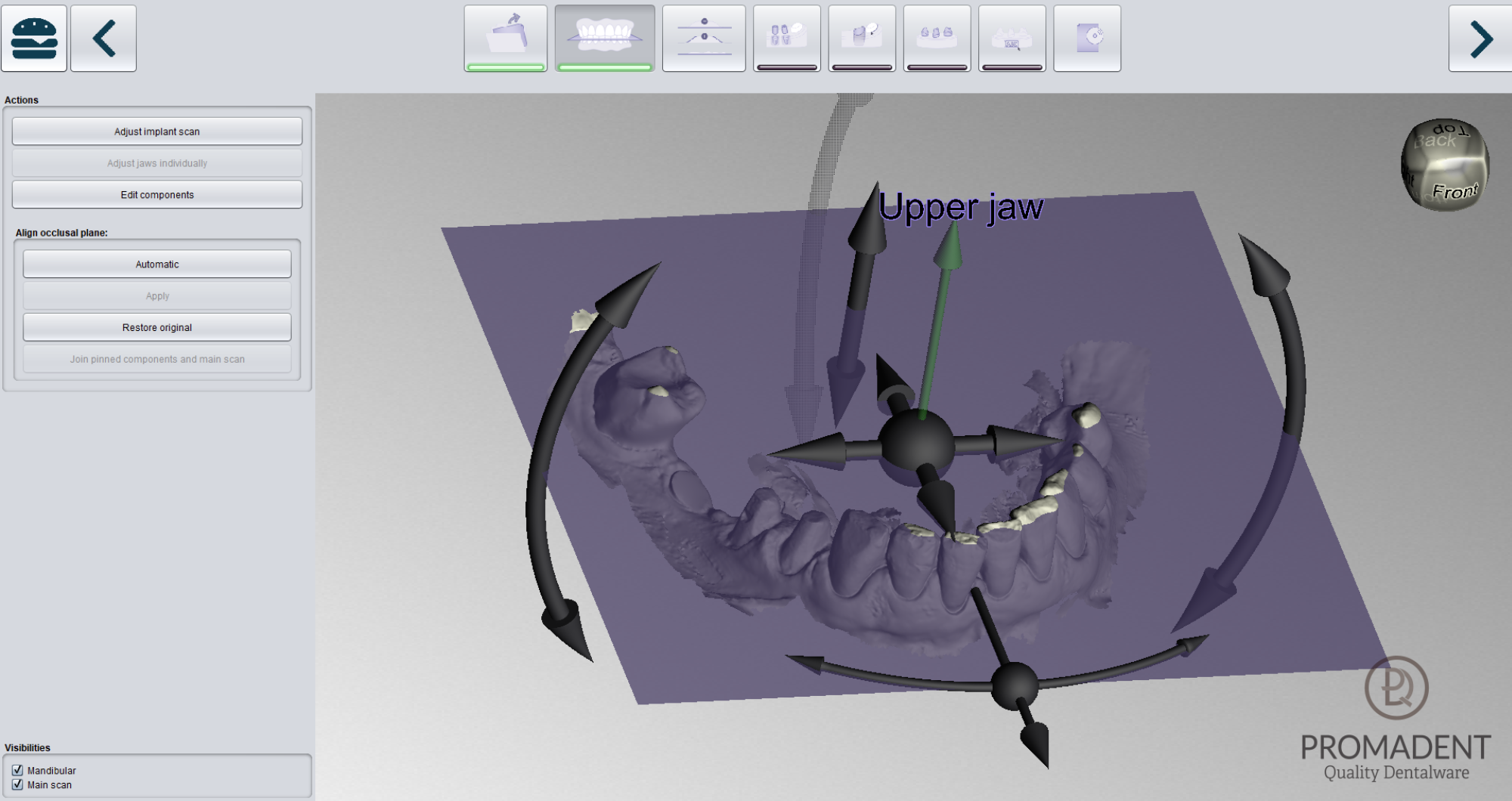

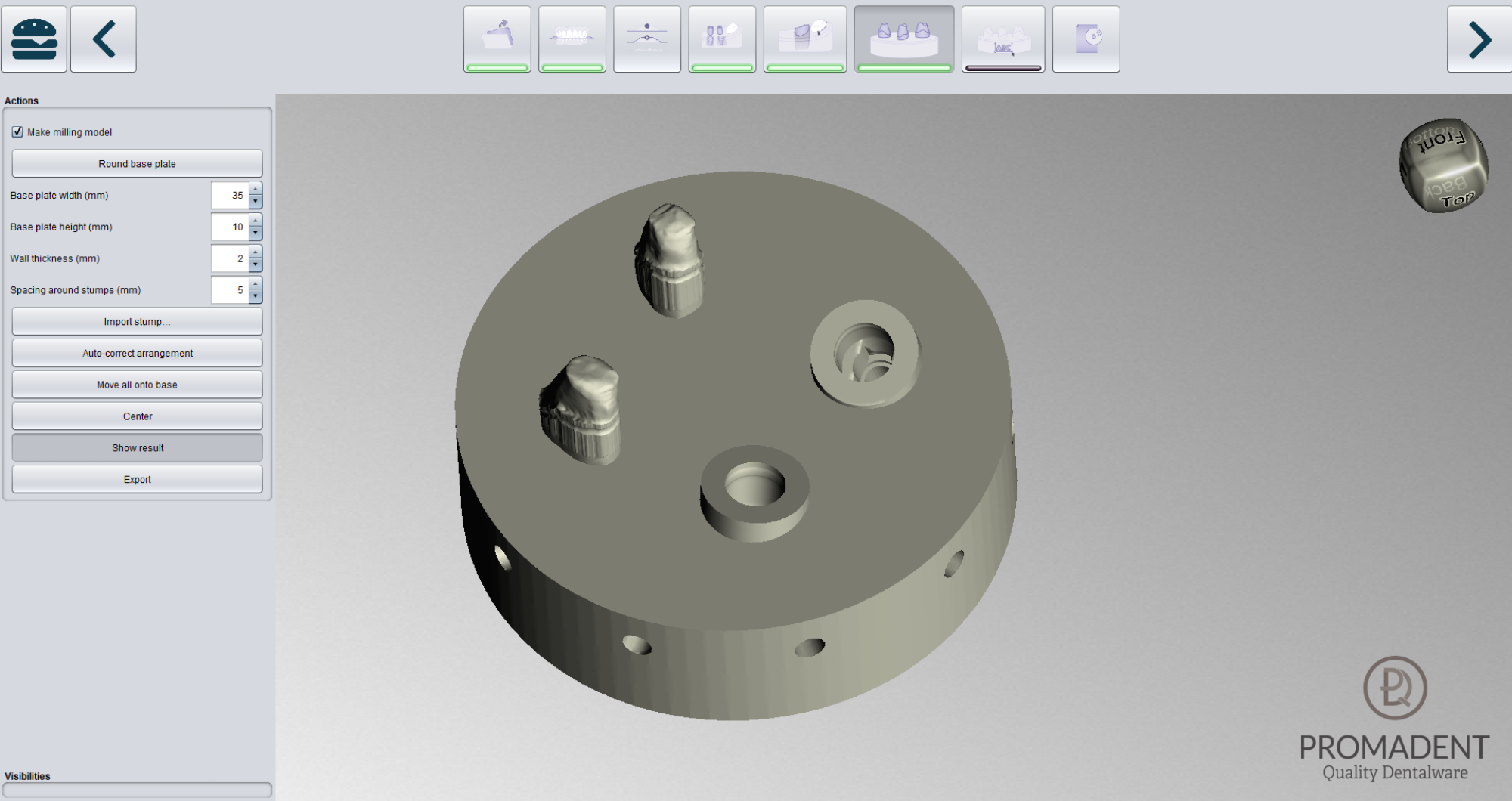

- Individual design of the milling model base geometry

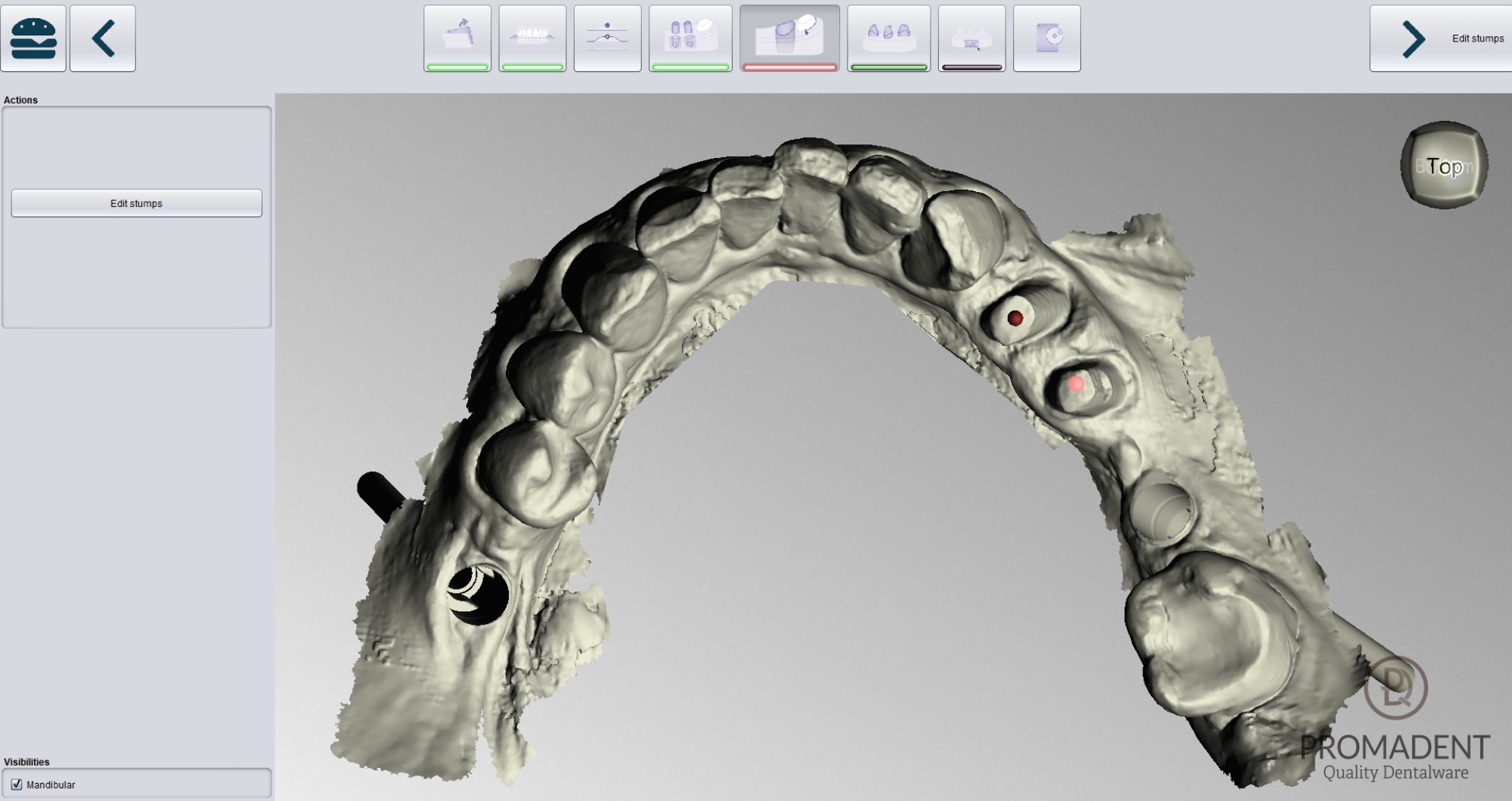

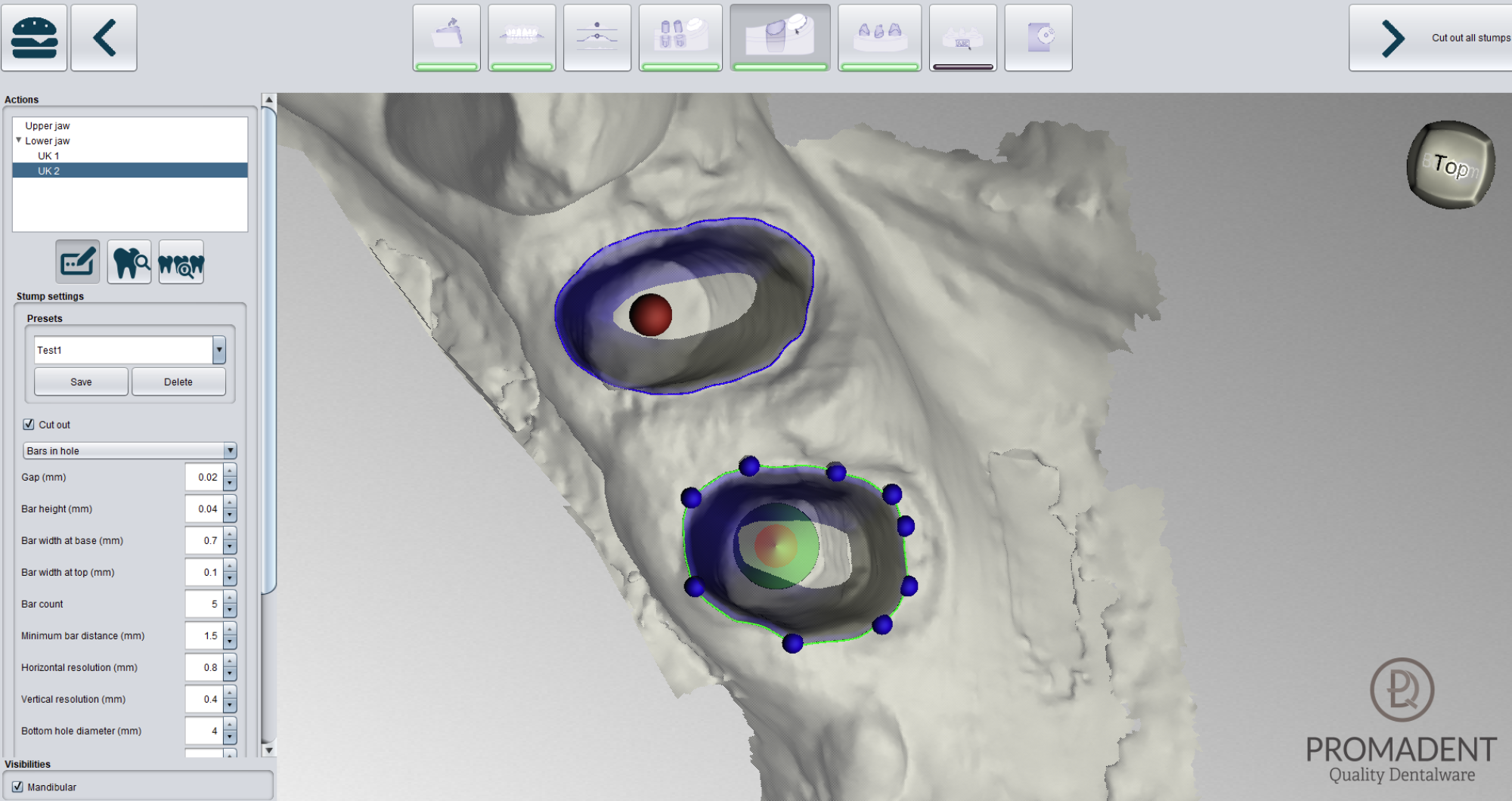

- Fast adjustment for height and spacing of dies

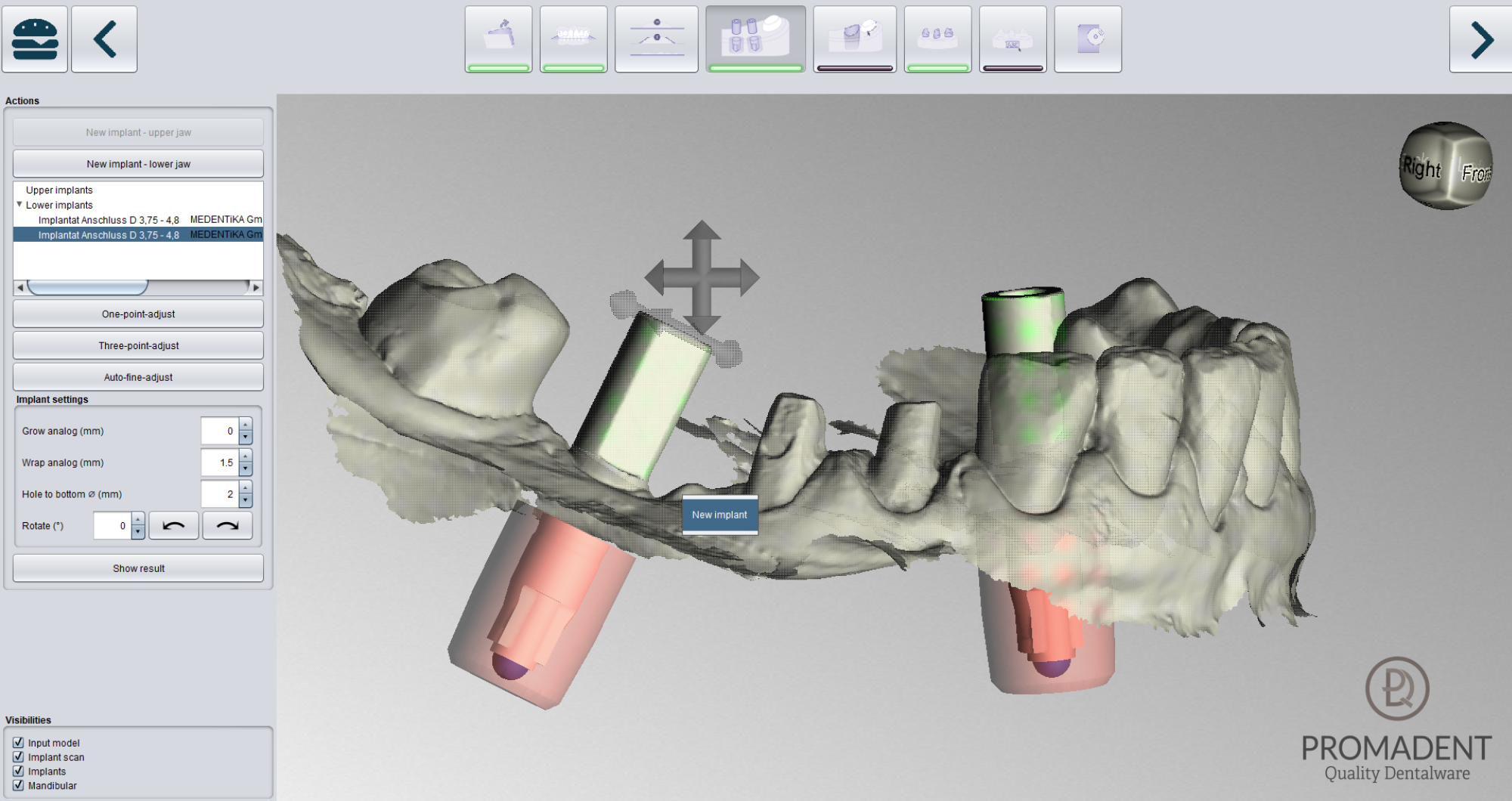

- Implant integration made easy

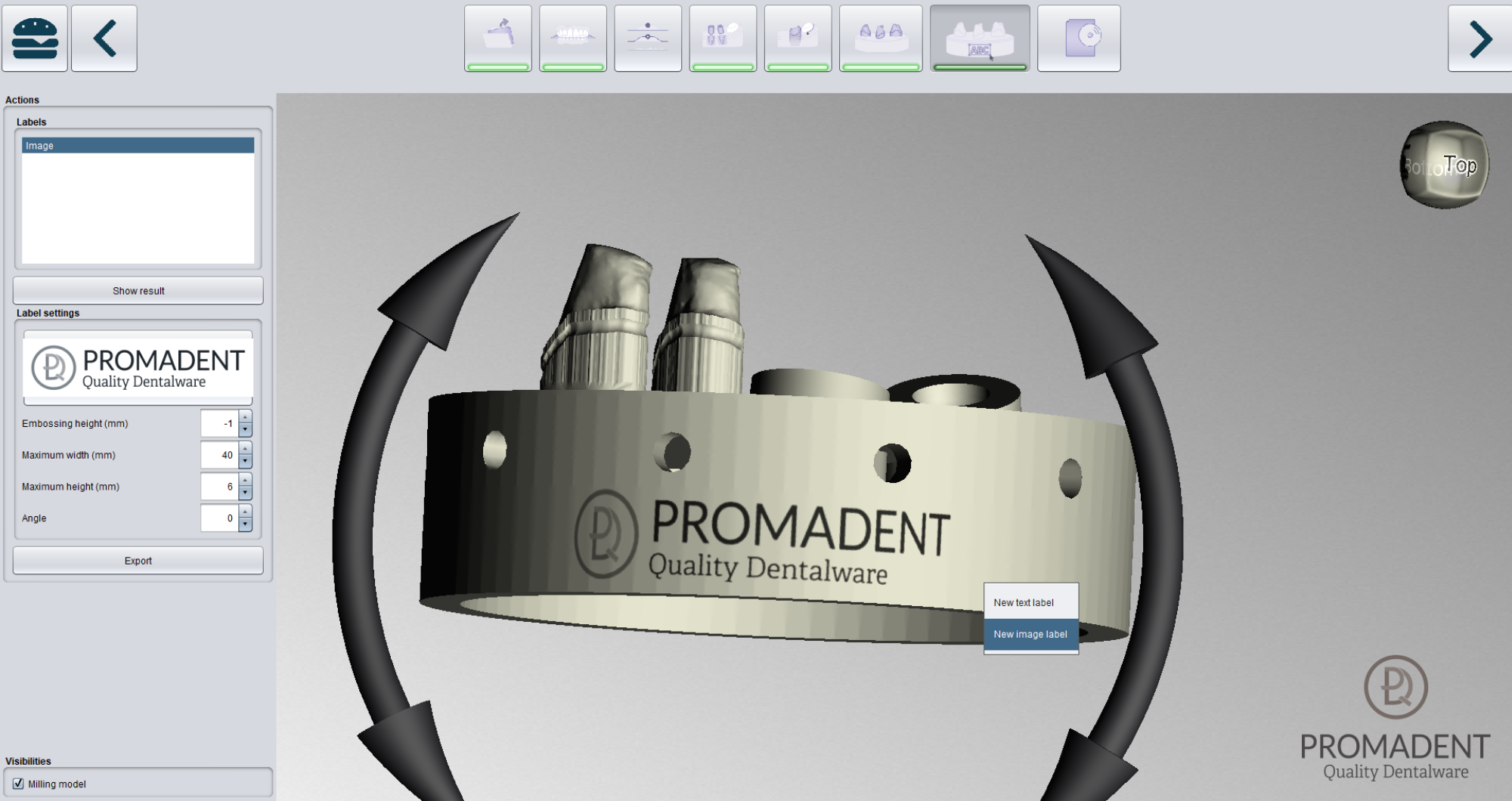

- Individualization of the milling model using automatic, high-resolution label tags

- Material-saving printing through hollowing

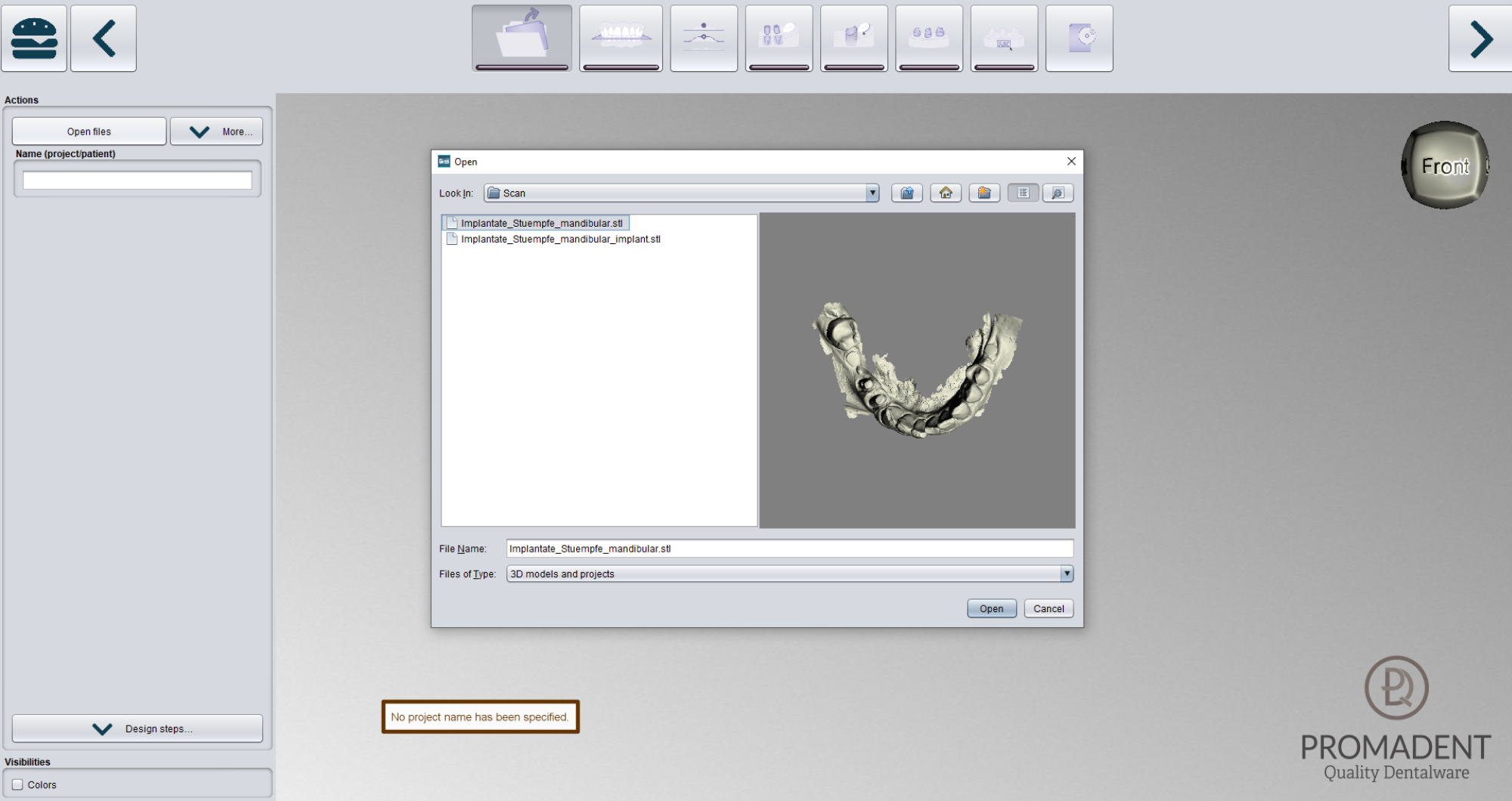

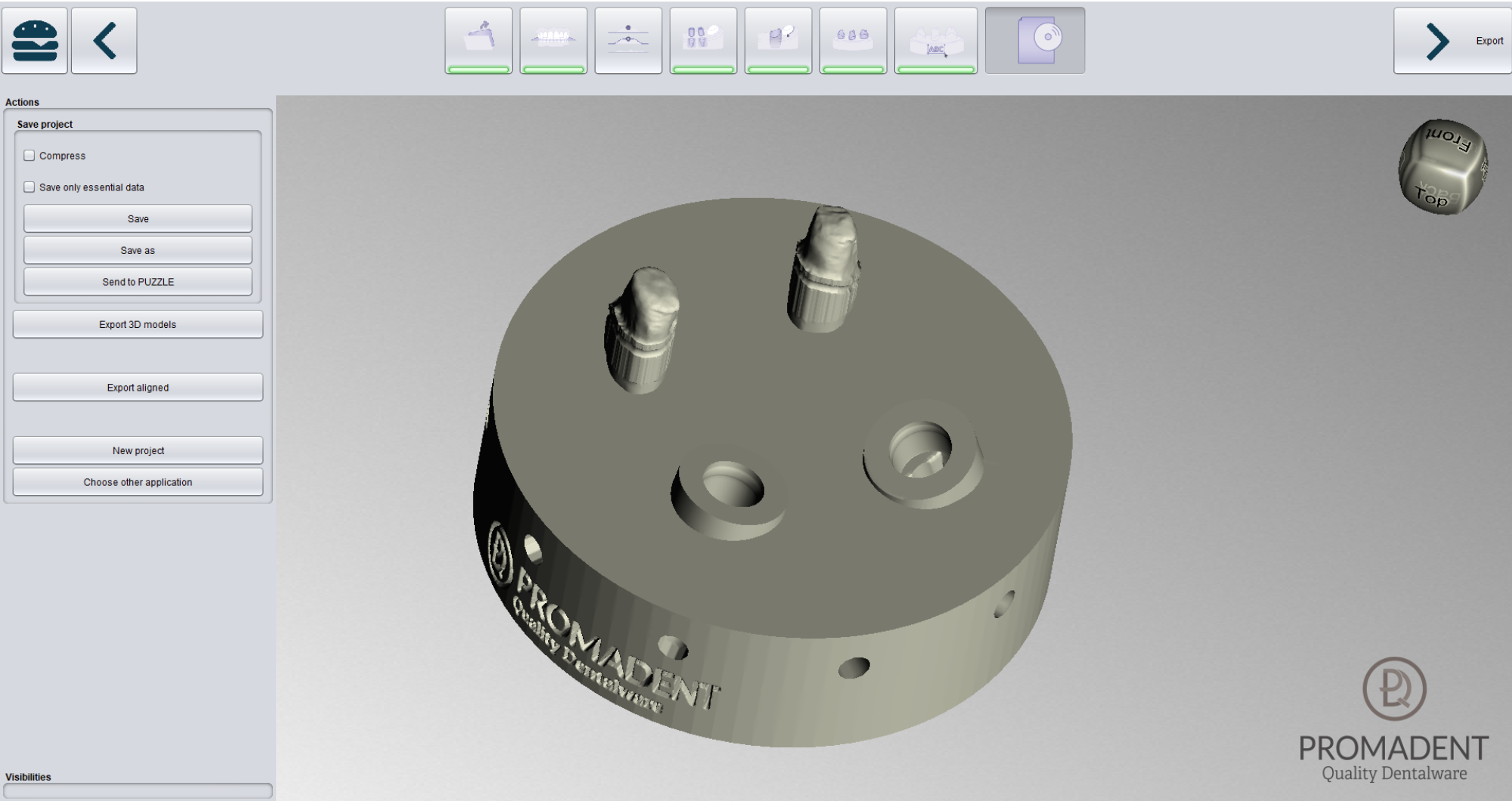

- Import & export of data in STL, PLY and OBJ formats

GOOD TO KNOW

System Requirements

- Windows 64 bit

- Min. 500 MB free file system memory, recommended 2 GB

- Processor min. 2 cores at 2 GHz, recommended 4 cores at 2.5 GHz

- Free RAM min. 8 GB, recommended 16 GB RAM

- Free USB 2.0 port

- Minimum screen resolution 1200 x 900 pixels

- Graphics card: e.g. HD Graphics 3000 DX10.1