With PUZZLE from IO scans to finished 3D print file

completely automated

Just 1 click and out of the 3D printer comes the physical model of the digital impression of your patients' jaw situation. With BiSS Puzzle - it couldn't be easier.

BiSS Puzzle automates and links the steps required to create a 3D printable model file from an IO scan file in the Integrated Auto-Assistance Workflow (iAW). BiSS Puzzle thus follows our claim: "Fast. Simple. Intuitive." to software products from Promadent, which is also the basis for all previous modules of the BiSS Dental Software Suite.

Thanks to the complete automation of the digital workflow for the creation of 3D-printable model files with BiSS Puzzle, manual operations that were still required in some cases are no longer necessary. Personnel resources, especially those of specialist staff, are conserved.

If, for example, 15 IO scan data sets are prepared for printing per day in your practice or laboratory, this quickly adds up to more than 160 minutes of working time per day. In a week, that's 13 to 14 valuable hours of work time.

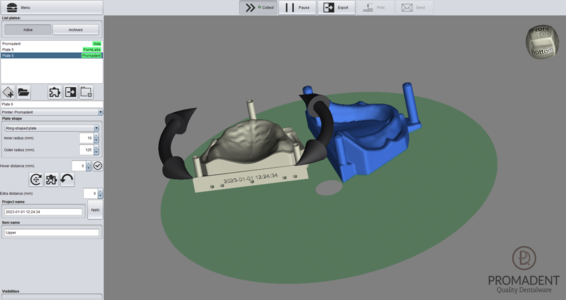

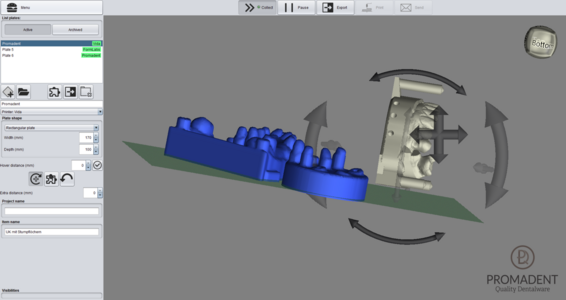

BiSS Puzzle independently accesses stored scan files from your intraoral scanner via Auto-File-Collect and imports them into the working environment. The scan files of the digital impression are then prepared into a 3D printable model file using the Integrated Auto-Design module (iAD), which is already successfully in use in the Biss Model Creator. Base, hollow out, attach base supports, label - these work steps are completely automated.

Now you only have to click on "Print".

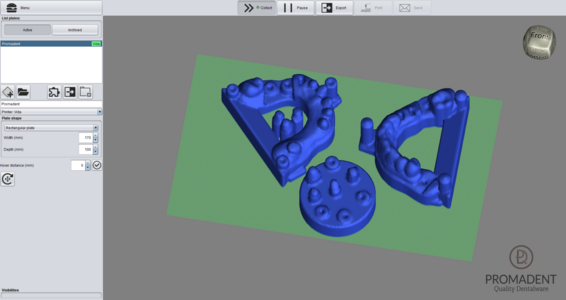

The 3D printable model datasets are collected and placed by BiSS Puzzle on the virtual 3D printing platform of your 3D printer (auto-nesting). You then only have to click on "Print". Once a platform is completely placed, the next one is automatically created.

Depending on the printer type, e.g. die fits with different parameters and printer accuracies are reconstructed fully automatically so that the desired fits are achieved.

Of course, the prepared model data sets (STLs) are available at any time for other advanced applications for BiSS users or can be sent to a partner milling center, for example.

iAW - integrated Auto-Assistance Workflow

- IO scan is stored

- model is constructed by background automation

- model pair is nested fully automatically on a virtual 3D printing platform

- immediately competent

- short-term implementation

- usable without IT expertise

- scalable without order volume limit

- independent of employees or outsourcing partners

- less costs

- good archiving and analysis

- compatible with any printer

- time optimization through automation

- stumps in 3D printing never cause stress again, thanks to individual adjustment of stump parameters directly in PUZZLE

- simply adapt the finished model for individualizations

- get ahead of the future now: Automation is the future

- no more stress with the search for skilled workers

Good to know

System Requirements

- Windows 64 bit

- Min. 500 MB free file system memory, recommended 2 GB

- Processor min. 2 cores at 2 GHz, recommended 4 cores at 2.5 GHz

- Free RAM min. 8 GB, recommended 16 GB RAM

- Free USB 2.0 port

- Minimum screen resolution 1200 x 900 pixels

- Graphics card: e.g. HD Graphics 3000 DX10.1 (we recommend to not use a graphics card from AMD / ATI RADEON)

User Manual

Recommended general stump parameters