BiSS redefine - MAJOR UPDATE 2022

After several months of development, we, as PROMADENT, present the first major update in 2023. In addition to many technical improvements, especially the appearance as a brand BiSS has been revised in font and form. New application names and fresh logos with matching colors in a modern look provide a better overview and pave the way for the international orientation. The 14 language packages are already available for download, more will follow. The goal is to make the BiSS software known in the dental world and to present completely new applications.

The Model Creator now becomes PRINT - nothing else changes.

In 1991, the Germans' favorite candy bar was renamed. Whether today's MARS GmbH used international linguistic jargons as motivation to launch Twix is of no importance to us as a promoter. Following the example of the "big players" (e.g. Microsoft Office), it was decided at our headquarters to give the software products a facelift. In addition, new structures complement the application matrix and we are now backing the international horse. And this is what the new roof of the popular software building will look like:

The BiSS success story

Already with the foundation in 2018, we inspired as an agile start-up with the innovative software BISS Model-Creator for the production of models based on intraoral scan data. Since then, the success story has continued steadily. When the software was first successfully used, the software logo was still an alien, but we as stakeholders were already starting to dream. "One day we will have a program offering like Adobe with Creative Suite," recalls Hindrik Dehnbostel, who as CADSPEED CEO is part of the founding team of the development team. The dream became reality: In January 2019, we launched the first release candidate (pre-release version) of BiSS Dental-Model-Creator. A good three years later - thanks in part to great feedback from enthusiastic users - a tool has been created that many laboratories would no longer want to do without in their everyday work. "Without the BiSS software, we would be stuck with our 16 CAD workstations," reports Ricardo Bell (CEO, CADSPEED Milling Center).

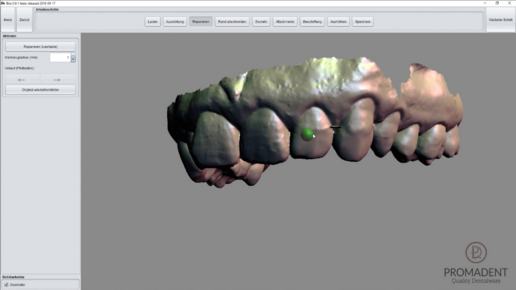

(Image left: BiSS Model-Creator 2018, Image right: BiSS PRINT 2022)

BiSS gets new turbo in source code and becomes up to 30% faster

Due to new development and future applications, the software for designing models on intraoral scans has been reprogrammed in months of maintenance mode. Calculations that were performed sequentially in series can now be multitasked in parallel. This gives the new PRINT software a performance boost of +30%. This new technology for calculating design steps will be used in further applications.

Next Steps

"We have developed properly in the lockdown sessions and are launching 3 new applications in the next few months. We also want to take off internationally, so we needed an English wording for some German-language programs such as milling models or bite templates, and have renamed everything once and designed the umbrella structure. The BiSS Dental Sortware Suite is to be the brand that unites all the applications. Model Creator is now PRINT, Milling Models is now MILLING, Tray Generator has become TRAYS for short, and Bite Templates including Support Pin Registrates has merged into LOCATE." Kimberly Krüger, CEO of Promadent

The new designs at a glance

PRINT is the software for digital dental model fabrication. Precise, printable 3D models can be created easily and quickly from digital impression scans. The scan data is shaped into a virtual dental model with an intuitive step-by-step workflow. PRINT can be used to define removable dies in the model or even complete segments. After purchasing the individual MILLING module, you can create a milling model from the previously defined dies in no time at all. With the "Implants" plug-in already integrated, you can quickly and easily integrate analogs into your model and create removable gingival masks. An extensive implant library is available to you for this purpose. Automatic hollowing and the creation of drainage channels are essential components for saving material and thus money. Jaw labels can be easily applied to the various base geometries and are an aid to patient assignment. Progress can be saved and archived in a compressed folder at any time.

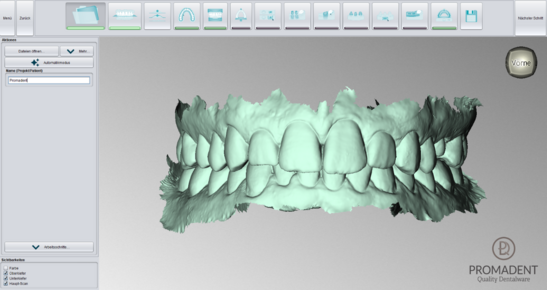

The new way to produce milling models is digital. With BiSS MILLING! Milling models can be designed in just a few minutes from intraoral and extraoral scan data imported in .STL, .OBJ and .PLY data formats. The step-by-step control already proven in PRINT is also a welcome relief in MILLING. This way, you will certainly succeed in quickly finding your way around the program. In this way, the digital dental laboratory runs through only a few, but sorted steps, such as defining the dies, base geometry, setting the height and distance to each other. The settings made are saved for the next job and ensure individualization of the program.

Create customized impression trays? Nothing could be easier with BiSS TRAYS! Developed in collaboration with dental technicians and dentists, TRAYS focuses on the essential steps relevant to impression tray design. With the individual module LOCATE, this is even possible for bite registrations and support pin registrations. The result is a well thought-out and streamlined workflow that guides you step by step to the finished product with numerous automatisms. However, the numerous optionally adjustable parameters ensure maximum flexibility, so that even the most specific customer requirements can be implemented. Individual trays can be designed in just a few minutes from intraoral and extraoral scan data imported in .STL, .OBJ and .PLY data formats. The digital dental lab thus goes through only a few, but sorted, steps such as defining the tray shape, blocking out the undercuts, creating wax walls if necessary, positioning the tray handle, labeling and perforating. The settings made are saved for the next job and ensure individualization of the program.

The creation of individual bite registrations and support pin registrations is child's play with BiSS LOCATE. Open file formats such as STL, PLY and OBJ can be imported into LOCATE from a wide variety of intraoral scanners. Developed in collaboration with dental technicians and dentists, the module focuses on the essential steps relevant to the design of bite registrations and support pin registrations. In this way, you run through a repair assistant in the workflow, which cleans up fragments of the digital impression in a supportive manner in order to design and print the bite registration and the support pin registration without interference. You have the option of designing your wax walls individually with grooves, with gutters, with a round end or with an open end. With the already integrated plugin "Pointer" you have the possibility to flexibly, individually and quickly combine a hole and a plate for the support pin with your predefined base. The result is a well thought-out and streamlined workflow that guides you step by step to the finished bite registrations and the finished support pin registration. BiSS LOCATE relies on numerous automatisms to get you to your goal as quickly as possible.

BiSS VIEWER is for open file formats such as STL, PLY and OBJ (color scans are also rendered). Now with intuitive operation and customizable visual properties. Change the look and feel of the colors of the models and backgrounds to your own liking, e.g. for presentation purposes. There are sophisticated displays, such as the Dual-Compare-View or an Explode-View. Have the size of each loaded object specified in a single- and multi-boundary box, but additionally individual geometry data. What we missed in other STL viewers is the function to move objects in 3D space in your position. We can now. =) Here is a real highlight for us with rarity value among the commercially available 3D viewers: Wall thicknesses can be easily checked with a colored representation. We love this function. We hope you do too. :)

3 new software products

The next revolution from the software workshop is to be given the label iAW and stands for Integrated Auto-Assistence Workflow - that much has been revealed.we are keeping a low profile here as to what is really behind the term and what the 3 upcoming new software applications are all about. Since apparently little has happened in the last few months, the dental world can be curious about what is now coming.